Description

DESIGNED AND MANUFACTURED IN LAS VEGAS, NV U.S.A.

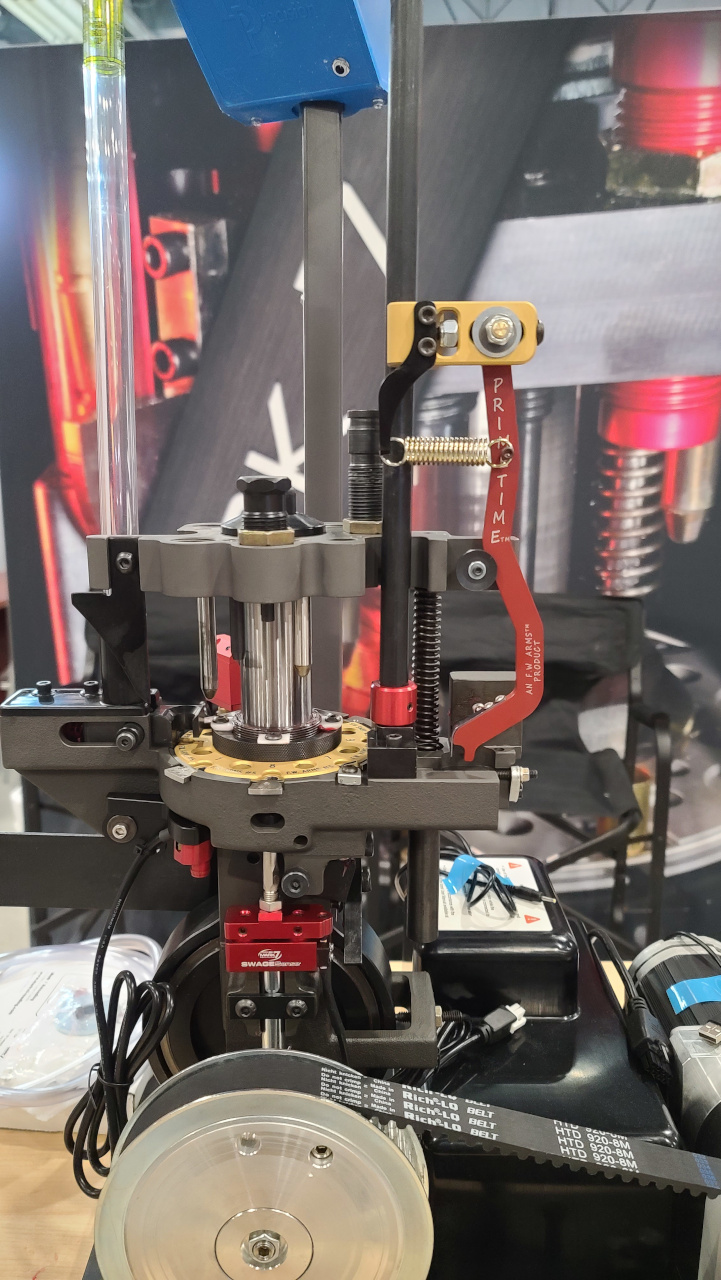

High speed decapping isn’t just for pistol rounds anymore. Achieve faster decapping cycle times in bottle neck rifle cases with the FW Arms™ Auto-Case Centering Decapper. The FW Arms™ Auto-Case Centering Decapper uses a patented design that centers the case with the decapping pin to eliminate case wiggle after indexing on a progressive press. If you reload with an autodrive you want to have as little down time as possible, no more delays at the top stroke of your press. No more decapping pins ending up on the outside of the case neck. Maximize your speeds with the FW Arms™ Auto-Case Centering Decapper.

WHY F.W. ARMS™?

No matter if you process 100 cases per batch or 100k cases, rifle or pistol brass, the F.W. Arms™ Standard Primer Popper the right choice when it comes to universal decappers. Not only does our decapper have our patented Auto-Centering shuttle, it’s also outfitted with an adjustable spring loaded tip/guide rod that eliminates virtually all primer pullback. F.W. Arms™ decappers are known to be build like tanks with tips designed for heavy use in the most demanding brass, able to easily handle crimped, sealed, crimped and sealed primers without fail; even multiple strikes on berdan primed cases.

WHAT CASES CAN THE STANDARD POPPER HANDLE?

This die was made for current automated presses on the market so it’s maximum parent case it can handle is 308 Win. This works great on pistol and rifle.

Each die comes with 2 replacement tips and our Premium Die Nut. Our Die Nuts are turned from solid steel hex stock, these nuts are still 1″ across the flats and measure .312″ thick. If you want some F.W. Arms Nuts click here!